Monitoring and Diagnostic

Monitoring and Diagnostic For HV equipment operators, understanding the health and condition of your key assets is critical to maintaining power quality and reliability of supply. PDT provides critical data, not only to better manage your HV assets but also to improve efficiency, extend the life, and increase performance. With experience and technical expertise in HV insulation and diagnostics, PDT is uniquely placed to deliver first-class global solutions offering a range of monitors, sensors, software platforms, and diagnostic laboratory services.

Power Quality Analysis Services

Detectable Faults

- – Harmonics and Interharmonics Analysis

- – Surges & Transient Analysis

- – Voltage Dips, Swell, Interruption Analysis

- – Undervoltages, Overvoltages, Current overload analysis

- – Imbalance Voltage and Current Analysis

- – Waveform Distortion: Notching analysis

- – Voltage fluctuations analysis Full Compliance with IEC 61000-4-30 Class A: Far surpassing the highest standards set by the Portable PQ unit complies with standards for aggregations, time clock uncertainty, flagging, and transient influence quantities.

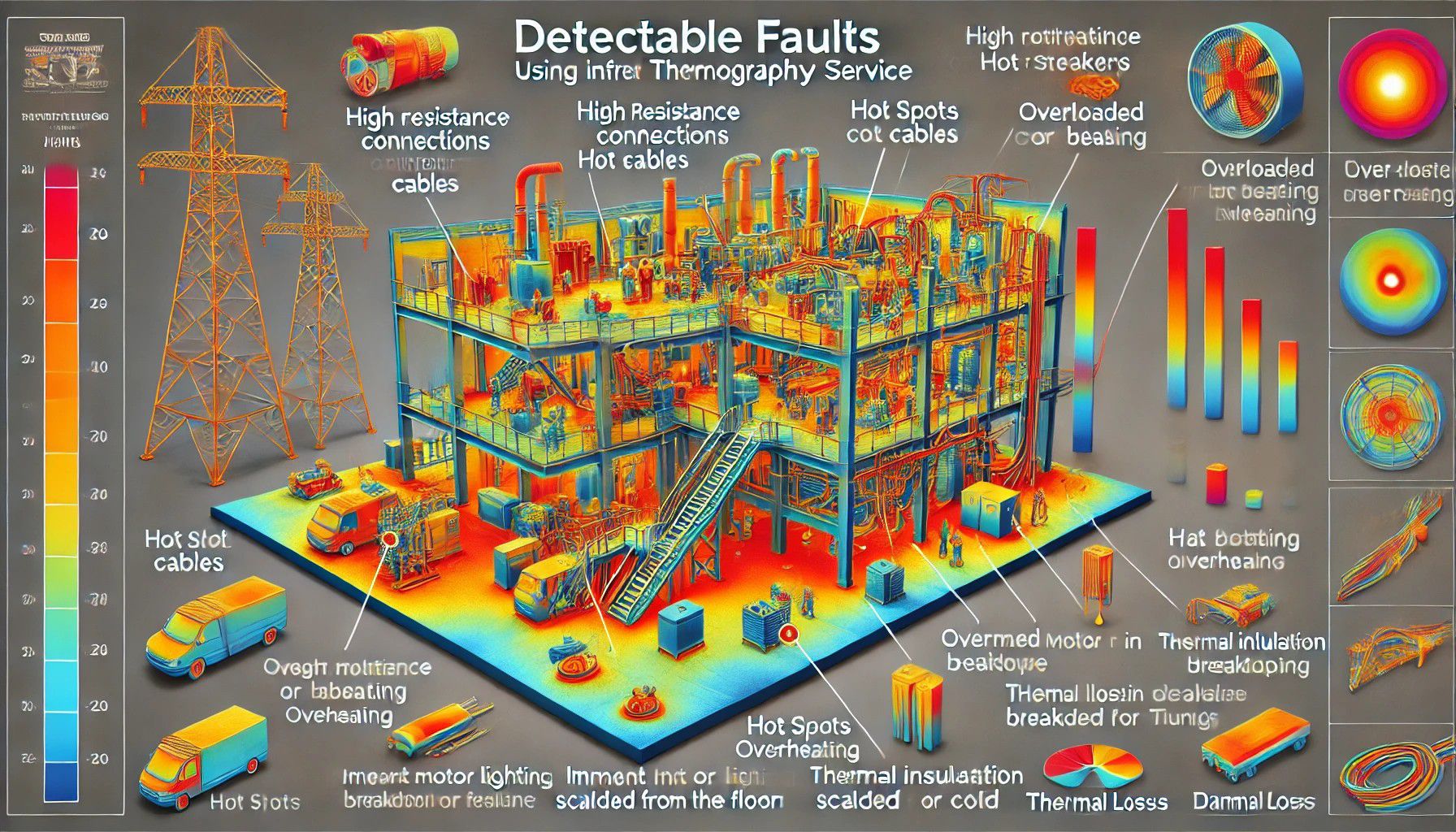

Infrared Thermography service

Detectable Faults

- – High resistance connections

- – Hot spots

- – Over loaded cables

- – Over loaded fuses or breakers

- – Imminent motor or conveyor bearing failure

- – Motor windings over heating

- – Overheating in distribution equipment

- – Phase load imbalance

- – Hot spots in high level lighting (easily scanned from the floor)

- – Heat build-up in overcrowded trunking

- – Thermal insulation breakdown (hot or cold)

- – Thermal loss

- – Damp ingress